So you’re about to start a project and know you need some wood. But what kind do you need? It’s not a simple question, and it’s an important one to get right.

There are many different kinds of wood and types of lumber — lumber being wood cut into planks or other usable pieces — and it’s easy to go wrong in the buying process if you skimp on research and planning.

Though it might seem tedious at first, it’s worth learning about the different kinds of lumber that are available, their distinguishing characteristics, and which ones are best suited to which applications. Once you start reading, you’ll find it’s actually pretty interesting. Wood has so much history, having been widely produced and used for making things for centuries.

As a result, everything about wood – from the way it is categorized and graded to the way it is cut and packaged – has been carefully thought out and painstakingly tested and improved over many years. There is also a truly mind-bending number of different types of wood, each with its own unique qualities.

The two main lumber categories are softwood and hardwood. Softwood, which comes from conifer or evergreen trees, is softer and cheaper. Pine, spruce, fir, and cedar are softwoods. Hardwood is harder and more expensive and comes from deciduous trees or trees that lose and regrow their leaves on an annual basis.

These types of trees take longer to grow than conifers; hence, their wood is costlier. Mahogany, walnut, and oak are examples of hardwoods.

For most home improvement projects, or to make things you don’t mind getting dinged and dented, you’re going to want to use softwood. And softwood is the obvious choice for DIY projects where cost is a factor. If you’re an expert woodworker, or an aspiring one, and want to make a nice piece of furniture, you’ll probably want to choose hardwood.

Hardwood is also famously used for flooring, where hardness is key. Keep in mind that the names of softwood and hardwood can be misleading. Softwood can be every bit as strong and resilient as hardwood, even though its surface is more impressionable.

Most of what you’ll find at your average home improvement store is softwood. If you want hardwood, you may want to go to a specialty retailer to get the best selection.

Once you’ve determined the type of wood you need, it’s time to figure out how much you should buy and in what form. Lumber is sold both rough and surfaced (smooth), in a few different shapes, and in a lot of different sizes. It also comes in different grades. The bottom line is, you’re going to want to do your homework before heading to the store.

And when I say homework, I mostly mean math. If it’s not your strongest subject, grab yourself a calculator. In fact, even if you’re a math whiz, use a calculator. This is one of those situations where you really, really, really want to be sure you’ve got the right numbers.

When calculating the dimensions of the lumber you need, it’s important to know the difference between nominal and actual size. Nominal size is the size of a piece of lumber before it’s been smoothed. The smoothing process reduces the dimensions on all four sides.

Hence, the difference between nominal and actual size. Lumber is labeled and sold by nominal size, so when you’re calculating how much wood you will need, you’ll want to reference a table that provides actual sizes alongside the nominal sizes.

It’s also important to know what sizes particular types of wood come in, so you don’t plan on buying a certain number of pieces in size your local store doesn’t sell.

The charts we provide in this article show typical lumber dimensions for softwood, hardwood, and plywood (which can be made of softwood, hardwood, or a combination of both). They also list nominal sizes alongside actual dimensions, giving you everything you need to do all your calculations before you head to the store.

Softwood

Most of us have heard of a two-by-four (2” x 4”) and can picture it in our minds. It’s a piece of lumber that’s 2” thick by 4” wide. The dimensions don’t refer to length, only thickness, and width. Remember that 2” by 4” is the wood’s nominal size. Its actual size may be a bit smaller.

Softwood lumber comes in a variety of standard thicknesses: 1”, 2”, 3”, 4”, 6”, and 8”. And lumber in each of those thicknesses comes in widths that are standard for that thickness.

Softwood Lumber Dimensions-1BY

This chart provides nominal and actual sizes, in inches and millimeters, for softwood lumber that is 1” thick.

Softwood Lumber Dimensions-2BY

Softwood lumber that is two inches thick comes in a range of standard sizes. Notice there is no such thing as a 2” x 5”.

Softwood Lumber Dimensions-3BY

This chart shows the standard 3-by sizes. As this type of lumber gets thicker, you will find fewer options for width. And you won’t find any that’s wider than it is thick.

Softwood Lumber Dimensions-4BY

As shown in this chart, 4-bys come in nominal widths of 4”, 6”, 8”, 10” and 12” (one foot).

Softwood Lumber Dimensions-6BY-8BY

With 6-bys and 8-bys, your thickness/width options are 6” x 6” and 8” x 8”.

Softwood Lumber Lengths

Just like thickness and width, softwood lumber comes in standard lengths. These range from 6” to 24”, with a variation of 2” between length sizes.

Softwood for Construction

Softwood lumber for construction comes in its own range of thicknesses and face widths. It also comes with its own terminology and some variation in moisture content, which has an impact on actual dimensions.

Standard Softwood Lumber Sizes-Thickness

Construction softwood lumber is categorized into three different types based on nominal thickness:

- Boards: Less than 2” thick

- Dimension: At least 2”, but less than 5”, thick

- Timber: At least 5” thick

Actual thickness depends on whether the wood was “dressed” (surfaced or smoothed) when it was Dry or Green. Because Greenwood has a higher moisture content than Dry, its actual size will be slightly larger than Dry lumber of the same nominal size. Note that softwood designated for construction is “minimum dressed,” which means it is still relatively rough.

Standard Softwood Lumber Sizes-Face Width

Our chart lets you calculate the actual width of construction softwood lumber based on its thickness category, its nominal width, and whether it surfaced Dry or Green.

Softwood Lumber Patterns

Conveniently, softwood lumber is available in certain pre-cut shapes designed for specific purposes. This is known as “worked lumber.” Examples are flooring and deck pieces that are designed to fit together like a puzzle, shiplapped siding, and bevel siding.

Hardwood

Hardwood Lumber Dimensions

Hardwood comes in standard thicknesses, but not standard widths. Also, its nominal sizes are expressed in quarter inches. This chart lists nominal sizes alongside their equivalent “rough” sizes. (Rough sizes are the same as the nominal sizes, but expressed in inches instead of quarter inches – which, for most of us, makes them easier to understand.)

Hardwood also surfaced differently than softwood. Rather than being smooth on four sides, it is smoothed on one or two. As with all surfaced wood, there is a difference between nominal and actual size. Our chart converts nominal sizes to actual sizes for both types.

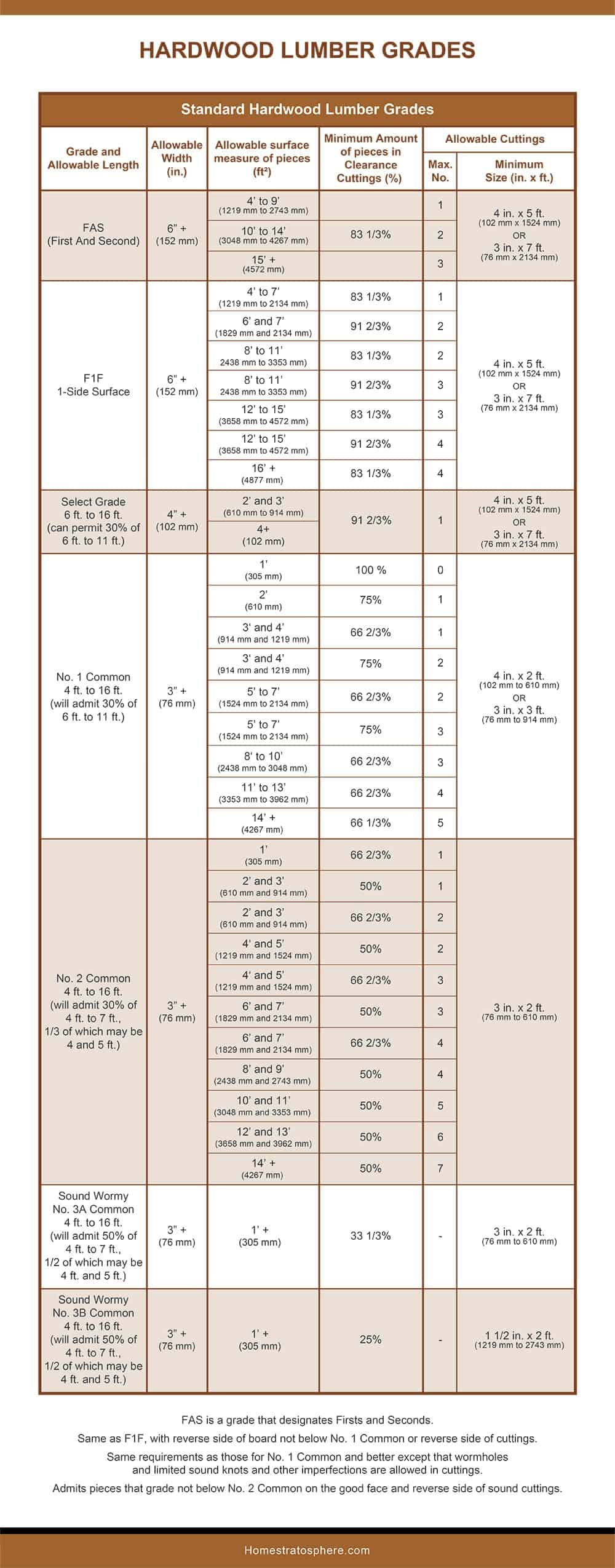

Standard Hardwood Lumber Grades

The grading of hardwood is both an art and a science. In a complex system that is almost like its own language, different types of wood have their own unique grading categories and criteria.

The basis of grading criteria, across hardwood types, is appearance. A piece of wood that meets the appearance standard for a particular grade is known as “clear.” But to earn a particular grade level, a parcel of wood must yield a certain surface area that qualifies as clear.

This is where science (or math) comes in. Charts full of numbers and even equations must be referred to in order to determine a hardwood’s grade.

To illustrate, say you want to buy a piece of First Grade hardwood. If the visual criteria for First Grade are “no knots,” it must be possible to cut the piece of wood into at least one, and no more than three, separate sections without knots for the wood to qualify as First Grade. And each clear (no-knot) piece must be of a certain minimum size – because just about any piece of wood can be cut into one to three perfect pieces if those pieces can be any size.

Our chart shows the specific allowable length, width, and surface measurements for each of the. seven standard hardwood grades. It also shows the minimum percentage of a parcel of wood that must be clear; the allowable number of separate, smaller pieces into which it may be cut; and the minimum size of each of these smaller pieces (cuts) required for the wood to earn each grade.

Standard Hardwood Lumber Grades-Lumber Surface

Measuring the surface area of a given piece of hardwood for the purposes of grading is no simple task. A strict set of rules must be adhered to, as shown in this chart.

Standard Hardwood Lumber Grades-Manufactured

Hardwood is graded primarily based on appearance, and grading systems vary by the type of wood. For example, the following grade definitions apply to Maple, Beech, and Birchwood, in particular:

- First: One face is perfect or nearly perfect, and there may be variations in color.

- Second: Knots are tight and sound except on the edges and ends, slight imperfections may exist, and the lumber can be used for flooring without waste.

- Third: There can be no holes (except very tiny ones) in the wood, and it must properly lay when used as flooring. Imperfections are acceptable.

- Fourth: Visual quality is not important, but it must be serviceable when used as flooring.

In addition to this grading system, there is a limited range of standard face widths and lengths specific to these types of woods. Standard face widths are 1½”, 2”, 2 ¼”, and 3¼”. In terms of length, First and Second Grade wood boards may be 2 feet or longer, while lower-grade boards start at 1¼ feet. The standard thickness of boards made of these types of woods is 25/32” (not quite one inch).

Standard Hardwood Lumber Grades-Oak

Oak, one of the most popular hardwoods, has its own unique grading system. Grades that may be applied to Oak are:

- Clear: Mostly heartwood with minimal character marks or discoloration

- Select: Heartwood and sapwood in all color variations are allowed, along with small character marks like knots, pinworm holes, and streaks

- No. 1 Common: Lots of variation in color, including heavy streaks, sticker stains, open checks, knots, and small filled knot holes

- No. 2 Common: Provides serviceable flooring but can have many imperfections

Oak lumber also has its own standard lengths. The higher the grade the longer the standard length. Oakwood may be categorized by “packaging.” Logically, “Standard Packaging” indicates boards that are slightly longer than those labeled “Shorter Packaging.”

Standard Hardwood Lumber Grades-Factory

Factory hardwood may be graded FAS, F1F, or Selects, and comes in standard thicknesses according to grade:

- FAS: Best factory lumber grade

- F1F: Second grade

- Selects: Third grade

Factory hardwood may also be graded No. 1 Common, No. 2A Common, No. 2B Common, Sound Wormy, No. 3A Common, or No. 3B Common. Standard thicknesses for the top three grades are 6” (FAS), 6” (F1F), and 4” (Selects). The standard thickness for all the other grades is 3”.

Plywood

What about plywood? Is it softwood or hardwood? More importantly, how is it measured?

Lots of construction projects call for plywood. It’s a favorite material because it’s both strong and light. Unlike the other lumber we’ve been discussing, plywood is not wood cut straight from the tree.

Rather, plywood is made by layering and gluing many thin pieces of wood together in a particular way that makes it especially strong. Plywood can be softwood, hardwood, or a combination of the two. The type you’ll find most often in your local hardwood store is made of softwood.

Plywood Dimensions

Like other lumber, plywood comes in certain standard sizes and types or categories. Size standards apply to both thickness and surface area dimensions.

Plywood comes in eight standard thicknesses, ranging from ⅛” (thinnest) to 1¼” (thickest).

Standard Plywood Sheet Dimensions

Plywood is sold in sheets, and there are five main sheet sizes based on the surface area. The most commonly used, known as a “standard” plywood sheet, is four feet by eight feet (4’ x 8’). Plywood sheets also come in four other sizes. These different-sized sheets are called “project panels.” Project panels can be 2’ x 2’, 2’ x 4,’ 4’ x 4’, and 5’ x 5’.

Standard Plywood Plies

When buying plywood, another important factor is the number of plies (or layers of wood planes) a piece of plywood contains. There are quite a variety of choices and different thickness options. For example, 3-ply plywood is available in both ⅛” and ¼” thicknesses. Standard ply counts are 3, 5, 7, 9, and 11.